NovaSterilis

“This partnership with AMT bettered our business. We developed a relationship with knowledgeable and well connected partner in AMT. This specific program was not only beneficial because it has allowed us to achieve a level of productivity we would not have otherwise attained, but it also has allowed us to successfully secure new market opportunities for our sterilization platform.”

— Tony Eisenhut, CEO

RESULTS

- Cost Savings of $25,000

- Total New Investments of $177,545

- New and Retained Sales of $350,000

- New Sales Backlog of Over $400,000

COMPANY

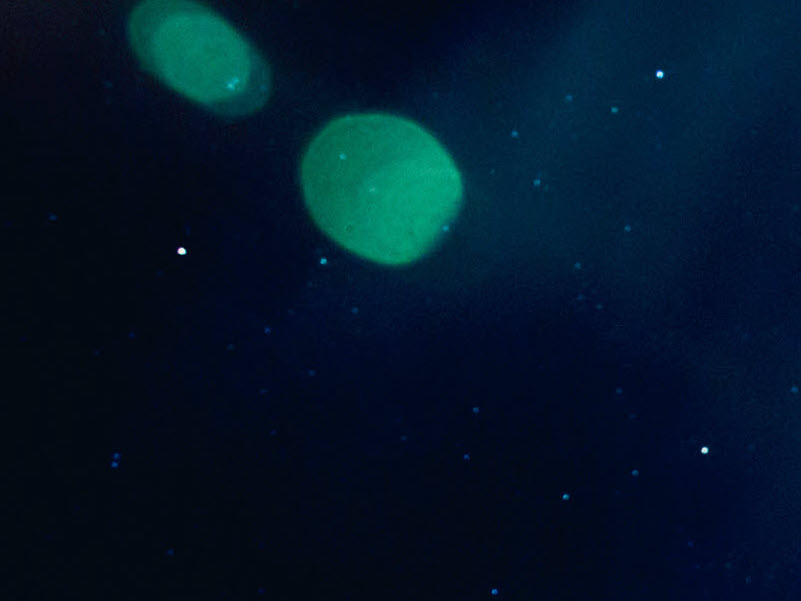

NovaSterilis is a medical equipment manufacturer located in Lansing, NY. They were founded in 2000 and currently employ 9 people. NovaSterilis’ technology is built around the utility of supercritical carbon dioxide (scCO2). Their equipment platforms are used to sterilize pharmaceuticals, medical devices and biomaterials used in regenerative medicine applications. In addition, this equipment has been used to create novel biomedical devices. NovaSterilis’ platform has been used to process orthopedic devices used in over 500,000 surgeries.

SITUATION

NovaSterilis sought AMT’s assistance with a project to redesign its’ operating software from the current design to a programmable logic controller (PLC). Additionally, the electrical design/layout was reconfigured for more efficient manufacturability of the Nova2200 supercritical carbon dioxide equipment platform. The redesigned software enabled additional process controls, which created new market opportunities. AMT’s partner, Jamex, Inc. provided the services and support for the project.

SOLUTION

Jamex designed the new architecture that leveraged the scalability of PLC control systems intended for the industrial and medical device manufacturing industries.

The new design allows for a user friendly, easily programmable and configurable control system. The new design permits NovaSterilis to take advantage of the built-in web-based operator interface, enhanced connectivity options, and expandability. HDMI and USB Ports built into the control system allows for integration of local operator interface via a touchscreen monitor (or mouse) without the cost of additional computers, operating system, Human Machine Interface (HMI) software, as well as printers that can be customized to meet end user reporting and record retention requirements.

AMT acted as a project manager for the effort, as well, as secured a NYSEG MAP grant to offset a portion of the project costs.